In order to get closer to the infrastructure industry, Vam Bend tries to simplify the work and bring ready-made constructions for all cases where we are dealing with the use of rebar. Vam Bend with its qualified team of engineers and experienced specialized operators, ensures that the final product is realized with high quality and without any delay.

The company has at its disposal the necessary professional and modern technical means, as well as means of transport to successfully carry out its functions. So, it provides security for the performance of the supply service with its own quality products and all the work is done in due time, meeting all the customer's requirements.

Vam Bend is ready to fulfill the customer's needs for high quality products at any time and in any case. Each order is passed and supervised by the responsible persons, such as the production manager and the engineer.

Experience crafting with factory machined rebar for precision construction! Our automated machines have pinpoint accuracy, ensuring each bar meets exact specifications, saving time and improving the quality of your build compared to traditional manual cutting and bending practices.

Our cages are created using advanced technology, including automated electric arc coil welding, and ensure that the final product is of high quality and performance. Automating our cages eliminates errors, reduces waste and maximizes structural integrity, outperforming manual methods.

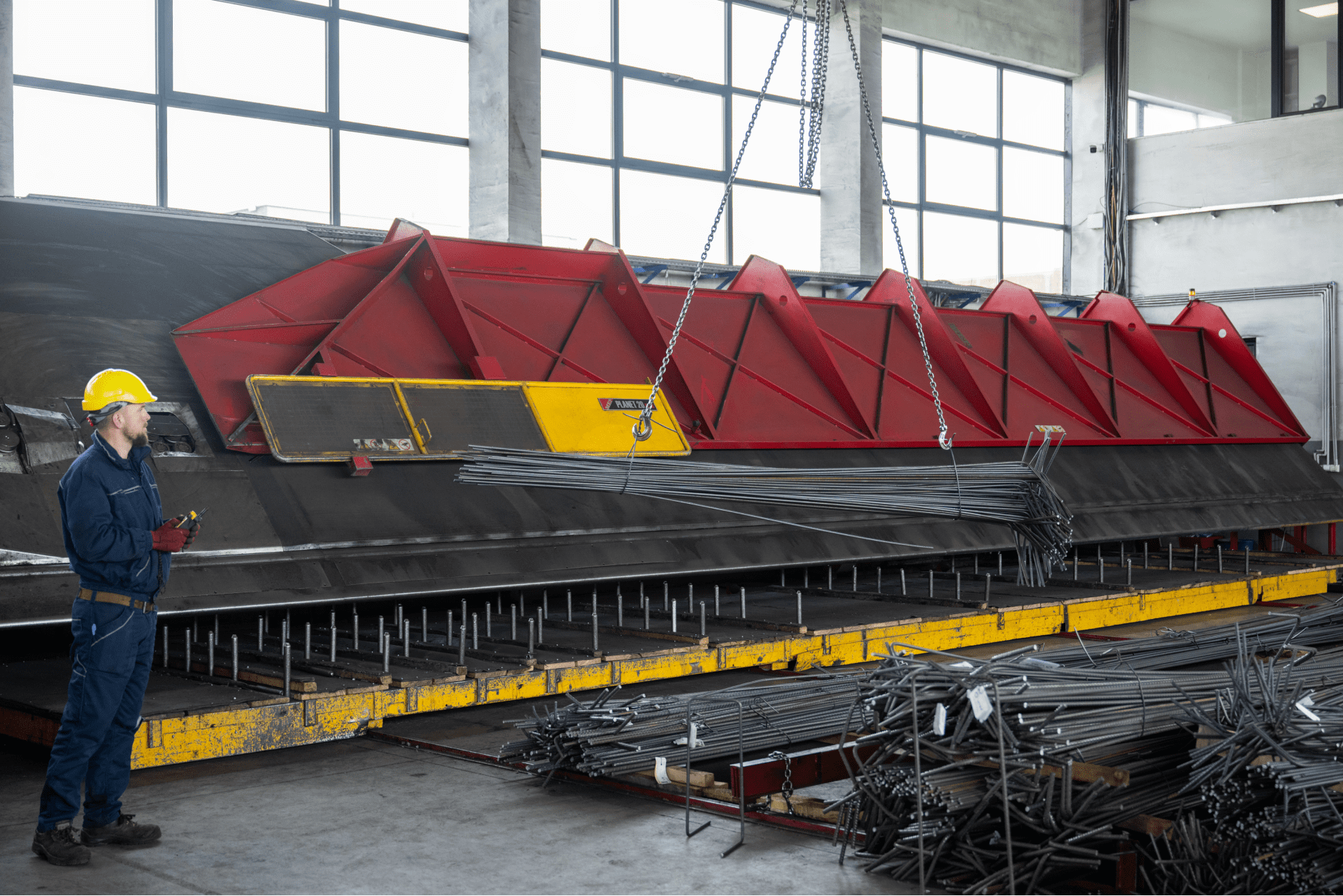

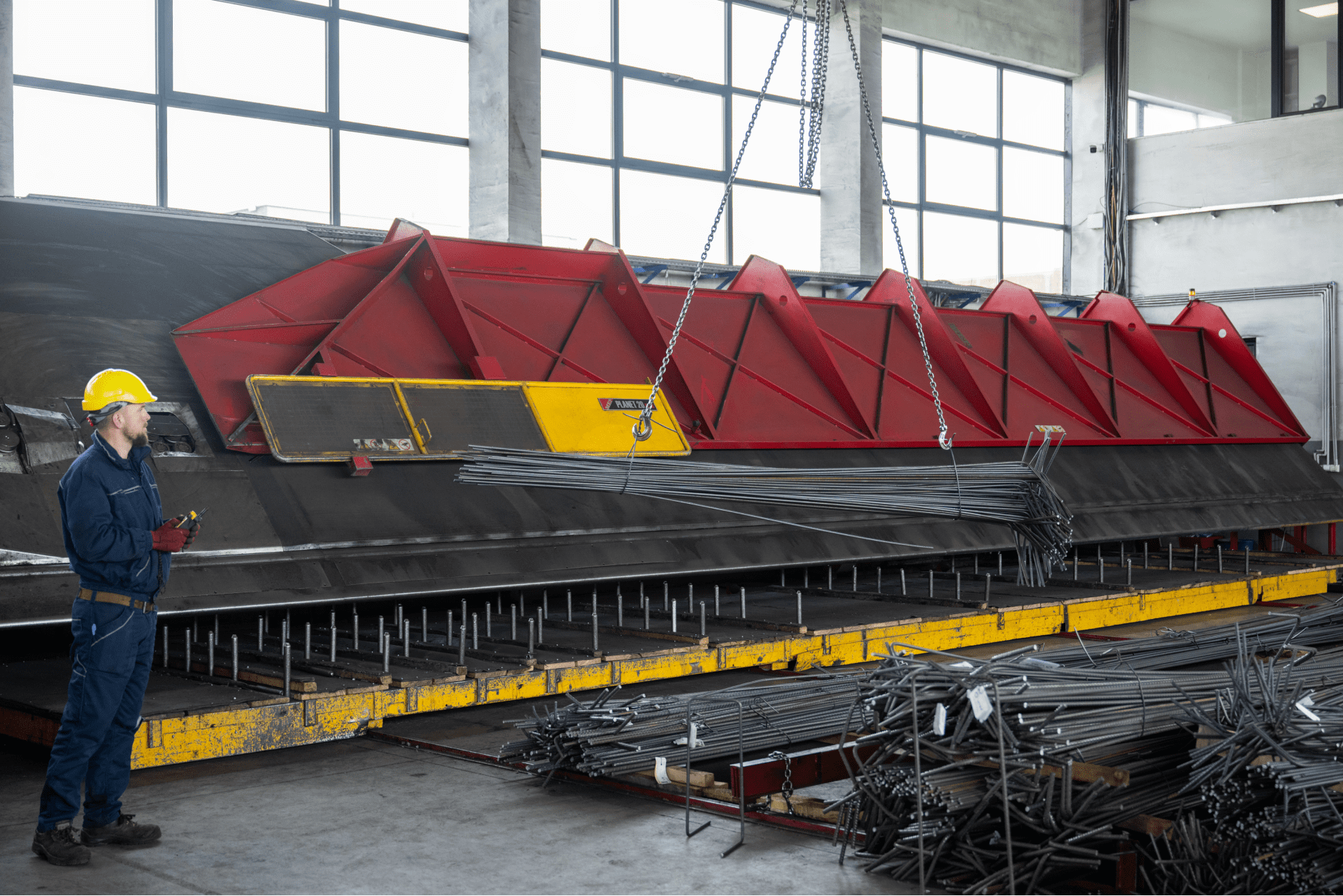

Our diaphragm walls are manufactured using the latest automation for incredible precision and durability. Unlike the labor-intensive manual approach, the advanced technology of our machines guarantees precision in bending, machining and shaping diaphragm walls. This results in reduced material waste and improved structural reliability compared to labor intensive methods.

Experience crafting with factory machined rebar for precision construction! Our automated machines have pinpoint accuracy, ensuring each bar meets exact specifications, saving time and improving the quality of your build compared to traditional manual cutting and bending practices.

Our cages are created using advanced technology, including automated electric arc coil welding, and ensure that the final product is of high quality and performance. Automating our cages eliminates errors, reduces waste and maximizes structural integrity, outperforming manual methods.

Our diaphragm walls are manufactured using the latest automation for incredible precision and durability. Unlike the labor-intensive manual approach, the advanced technology of our machines guarantees precision in bending, machining and shaping diaphragm walls. This results in reduced material waste and improved structural reliability compared to labor intensive methods.

Most construction companies employ a large number of separate machines for manual cutting and bending. Cutting and bending of steel bars for construction is done by unskilled workers, leading to inaccuracies and steel scraps which are estimated to be at least 5% to 8%. Cutting and bending takes place at the plant, which occupies a considerable area.